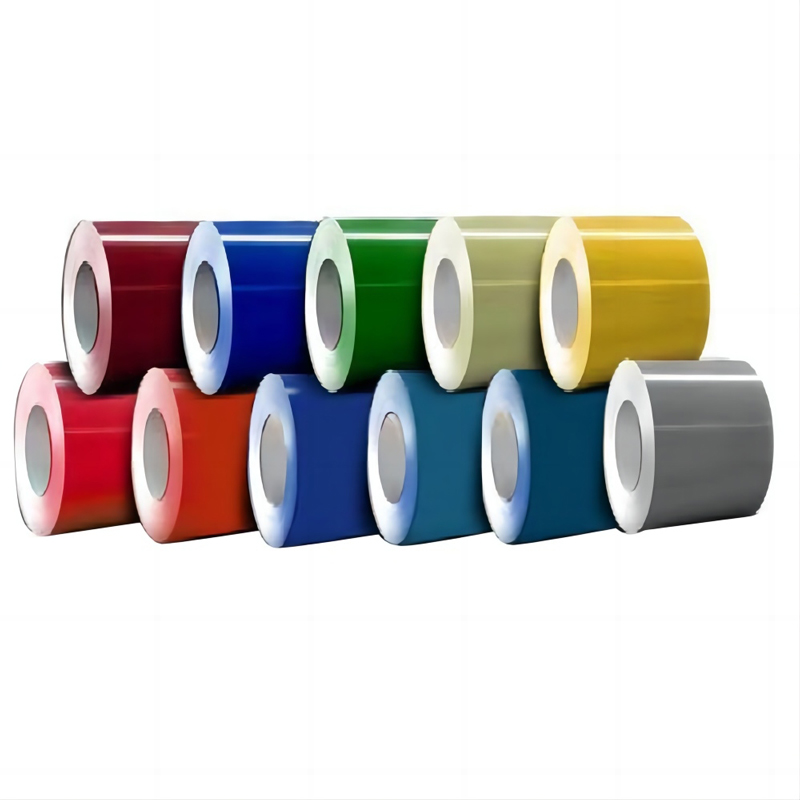

Painted Galvanised Steel Coil

PPGI rolls are lightweight, beautiful and have good anti-corrosion properties, and can be processed directly. The colors are generally divided into gray and white, sea blue, and brick red.

They are mainly used in the advertising industry, construction industry, home appliance industry, electrical appliance industry, furniture industry, and transportation industry.

Description

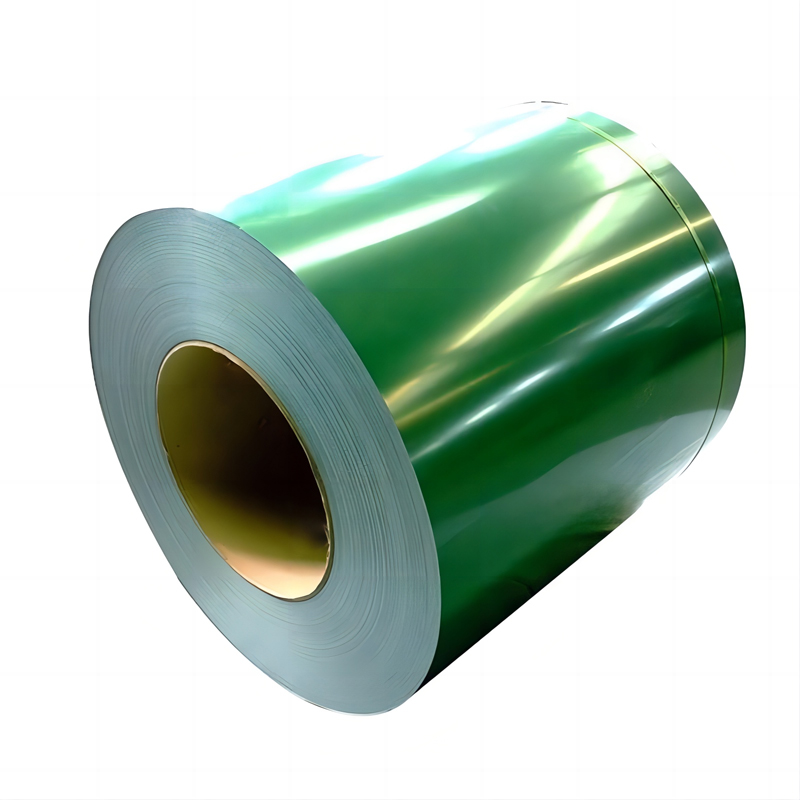

PPGI steel coil is a kind of composite material, also known as color-coated steel plate made of strip steel on the production line after continuous surface degreasing, phosphating, and other chemical transfer treatment, coated with organic paint and baked products.

Property& Specification

(1) Good durability and corrosion resistance and has a longer lifespan than galvanized steel plates

(2)Good heat resistance and is less likely to discolor at high temperatures than galvanized steel plates

(3)Good heat reflectivity

(4)Processing performance and spraying performance similar to those of galvanized steel sheets

(5) Good welding performance

(6)Good performance-price ratio, durable performance, and extremely competitive price

Material Thickness: | 0.10mm-1.5mm |

Max Coil: | 3-8tons |

ID: | 508mm, 610mm |

Width: | 660-1150mm |

Zinc coating: | 10-400g/m2 |

Color Coating Material: | PE, SMP, HDP, PVDF |

Width/Length Tolerance: | +/-3mm |

Max Coil Weight: | 8tons |

Whether architectural designers, engineers, or manufacturers, galvanized steel sheets have been widely used in industrial buildings, steel structures, and civil facilities, such as garage doors, gutters, and roofs.

The product obtained by coating organic coatings on hot-dip galvanized steel panels is hot-dip galvanized color-coated panels.

In addition to the protective effect of zinc, the hot-dip galvanized color-coated sheet also has an organic coating on the surface that protects and prevents rust and has a longer service life than hot-dip galvanized sheets.

PPGI Coil Coating Types

Polyester

Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon modified polyester

Namely (SMP), the hardness, abrasion resistance, and heat resistance of the coating film are good, as well as good external durability and chalking resistance, gloss retention, average flexibility, and medium cost.

High durability polyester

Namely (HDP), excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good paint film adhesion, rich colors, and excellent cost performance.

Polyvinylidene fluoride

Namely (PVDF), excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited colors, and high cost.

Packing & Delivery