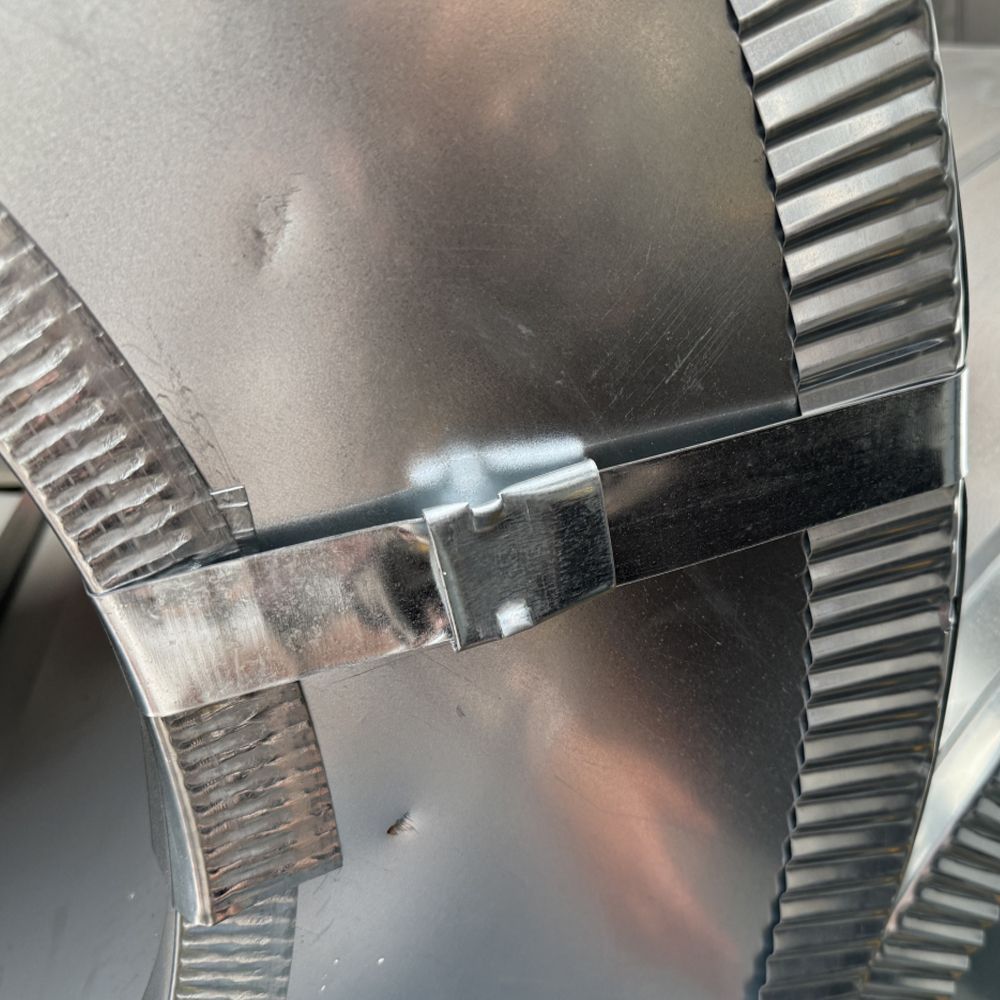

Wholesale 0.13-4.0 mm 40-300G/M2 Q195 Q215 Q235 Q275 Hot DIP Galvanized Steel Coil

Galvanized steel coils have the characteristics of strong corrosion resistance, uniform and dense galvanized layer, excellent wear resistance, beautiful appearance, and easy processing and welding. They are widely used in various fields such as construction, furniture, automobiles, and electrical appliances. Galvanized steel coils have the characteristics of strong corrosion resistance, uniform and dense galvanized layer, excellent wear resistance, beautiful appearance, and easy processing and welding. They are widely used in various fields such as construction, furniture, automobiles, and electrical appliances.

Contact us:

Company Name: Shandong Huanyu Shengshi Steel Co., Ltd

Address: Room 2319, Building 8, Wanda Plaza, Mount Taishan District, Tai'an City, Shandong Province

Whatsapp:+86 19026213383

Email: info@glbsteel.com

| Product Name | Galvanized steel coil |

| Standard | AISI, ASTM, GB, JIS |

| Certifications | ISO 9001-2015, SGS, BV |

| Grade | SGCC, S350GD+Z, S550GD+Z, DX51D, DX53D, DX53D |

| Thickness | 0.12-4.0MM |

| Width | 600-1500MM |

| Zinc coating | 40-275G/M2 |

| I.D. | 508-610MM |

| Weight | 3-8Tons |

| Technique | Hot rolled/Cold rolled |

| Spangles | Large spangles, Regular spangles, Small spangles, Zero spangles |

| Package | Export packing standard |

| Payment | TT, L/C at sight |

| Remarks | Customization is acceptable |

Steel coil preparation: Firstly, the selected high-quality steel coil is cleaned and surface treated to ensure a clean surface and remove any impurities and oxides.

Zinc aluminum coating preparation: Prepare the liquid zinc aluminum alloy solution, usually by heating the aluminum and zinc alloy solution to a liquid state.

Continuous galvanizing: The surface treated steel coil is coated with a layer of aluminum zinc alloy solution through a coating line, and then the alloy coating is cured on the surface of the steel coil through heating and cooling processes.

Adhesive baking: The steel coil coated with aluminum zinc alloy is sent into the baking furnace to bake and cure the alloy coating, ensuring its adhesion is firm.

Cooling and coiling: After baking, the steel coil is cooled by a cooling device, then cut into the required length and rolled into coils.

Packaging and quality inspection: Finally, pack the aluminum zinc coated coils and conduct quality inspections to ensure that the coating is uniform, firmly attached, and meets relevant standard requirements.

| Surface treatment type | Code | Feature |

| Chromic acid treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Have certain corrosion resistance, good paint performance, and prevent rust |

| Oiled | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate paintin |

Tai'an Huanyu Shengshi Steel Co., Ltd. was established in 2012, specializing in the production of steel products and enjoying a good reputation. Our main products include galvanized coils, galvanized sheets, PPGL tiles, PPGL coils, aluminum plated coils, aluminum plated plates, channel steel, steel bars, etc

These products are mainly used for infrastructure construction in highways, railways, water conservancy engineering, electricity, and soil and water conservation. We have established advanced internal testing laboratories and a strict quality control system from raw material to finished product testing.

Q: What can you buy from us?

A: Galvanized sheet, galvanized coil, stainless steel, PPGL sheet, PPGL coil, etc

Q: Can you give me a sample?

A: Yes. And it's a free sample.

Q: What are the payment terms?

A: T/T or L/C. Other issues can be resolved through negotiation.

Q: What is the delivery time?

A: Within 3-20 days after confirming the order, the detailed delivery date should be determined based on the production season and order quantity.